We make your ideas our mission!

Your wishes and requirements come first with us – just as much as quality! From flavoured milk-based drinks to organic milk products – in our traditional dairy factory in Obergünzburg we devise innovative product solutions from your ideas, with quality guaranteed!

Our many years of experience and our passion for the development, manufacturing and bottling of milk products ensure that we stand out as a trustworthy partner for contract packing and private labelling.

Success starts with quality

The recipe for success? The right idea and the right skills – and top quality! We guarantee a seamless production process from the raw material stage right through to shipping of the products. This is based on high food safety standards, certified raw ingredients from specially selected suppliers, innovative technologies, and multi-stage monitoring in accordance with HACCP guidelines.

Each product is manufactured according to current statutory standards. For the international market, we of course also include country-specific regulation requirements in the development of the product.

And that’s not all – we’re only happy when you’re happy. For this reason, we are at your side to give advice and guidance throughout the entire process, right through to the end product.

From a single source

At Saliter you can get everything you need, from the initial idea, to the development and manufacture of the product, through to bottling – all from a single provider. Many of our process technologies at our site in Obergünzburg exceed conventional dairy standards. This means we can achieve the precise blend of large, medium and micro components to create the recipe for a successful product.

Whether you’re looking for standard products or customised solutions, our state-of-the-art technologies and the high levels of qualification within our workforce guarantee a first-class solution exactly tailored to your needs. If preferred, you can send us your specifications for particular ingredients, and we can then use these for your individually customised products.

We have our own in-house pilot system where we can test recipe suggestions in the development stages, and thus work out the ideal ratio of ingredients. A two-stage sterilisation process guarantees that the end product has a long shelf life and retains its freshness. And finally, we bottle your milk blend in the required quantities and container unit.

We are happy to help you

Do you have an idea for a specific product, or a question about our services? Or are you interested in selling one of our popular products under your own label? Then please get in touch. Together we can create solutions and achieve real added value!

Our packaging options

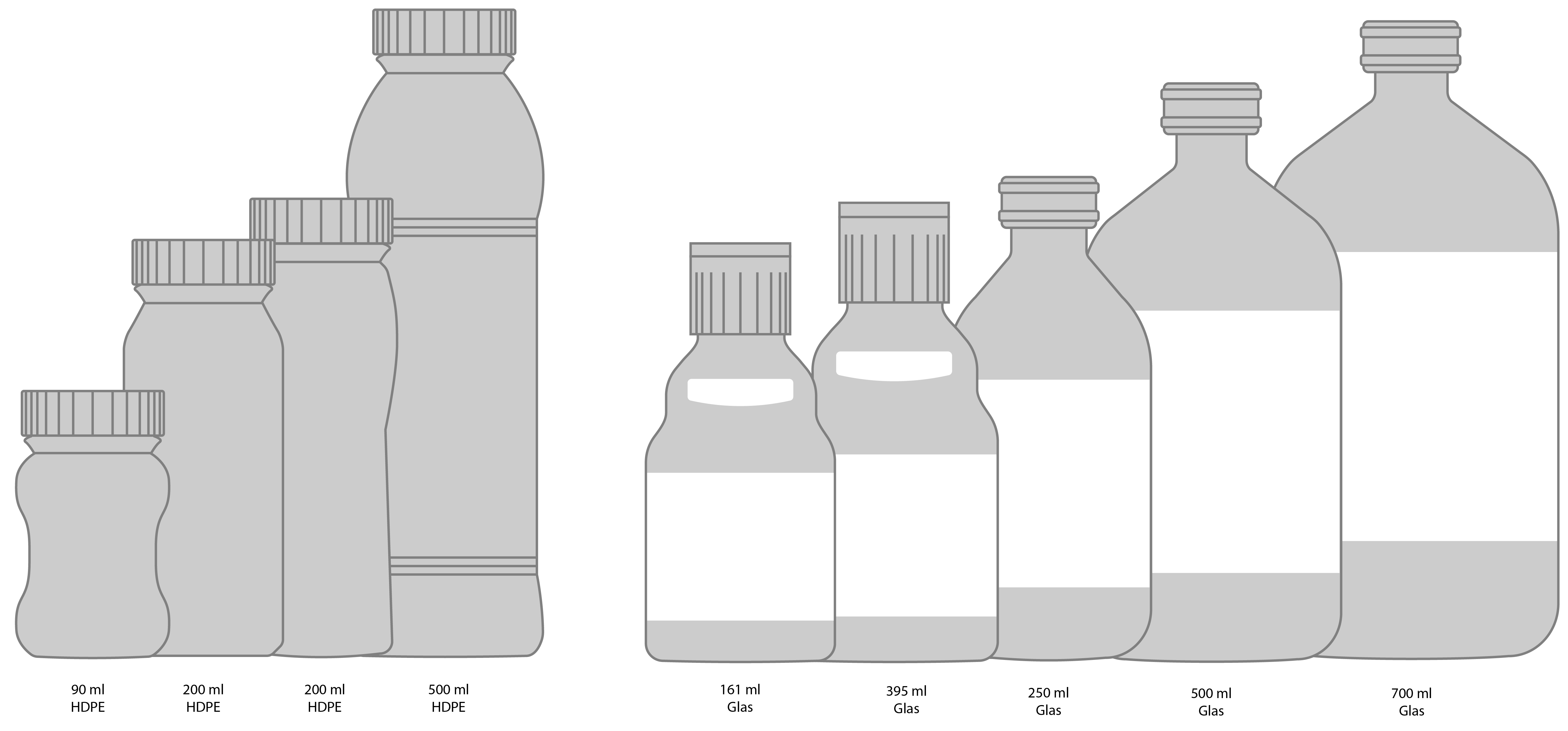

The right packaging not only protects the product, but also serves to attract the eye of the customer and encourage sales. Our packaging options combine design and function: as well as clear glass bottles, we also offer HDPE bottles. We are happy to advise on which packaging is the best for your product.

RTF-/RTD-Flaschen 200 ml

- White multi-layer HDPE bottle with aluminium lid and screw cap

- Full body sleeve with perforations for opening (sleeve is wrapped around bottle and screw cap = tamper-proof packaging).

- Integrated scale in sleeve not possible

(bottle is not transparent) - 24 (6) bottles per tray + shrink wrap

Palletising:

- IPPC 120 x 80 cm

- 16 (56) trays per layer

- HGV transport: 7 (5) layers = 2,688 (1,680) bottles

- Transport by ship: up to 8 layers = up to 3,072 bottles

Minimum production quantity: 5,000 litres

RTD bottles 500 ml

-

- White multi-layer HDPE bottle with aluminium lid and screw cap

- Suitable for standard NUK teat

- Bottle sleeve covers body of bottle

(does not cover the screw cap) - 12 (6) bottles per tray + shrink wrap

Palletising:

- IPPC 120 x 80 cm

- 15 (31) trays per layer

- HGV transport: 6 (6) layers = 1,080 (1,116) bottles

- Transport by ship: on request

Minimum production quantity: 10,000 litres